For over 50 years, Edburton has been trusted by private clients, Local Authorities and Districts across the South and beyond to plan and execute engineering drainage and soakaways projects.

We range from 24 hour round the clock emergency relief, to the construction of complete new systems.

- Foul & storm main drains installation

- Connections to existing runs

- Overpumping

- Pumping station installation

- Rising and pumped mains

- Construction of main foul sewer treatment plants

- Holding tanks

- Oil interceptor tanks

- Outfalls & headwalls

- Attenuation systems

- Balancing ponds

- Filter drains and deep bored soakaways

CASE STUDIES

SHELTER HALL, BRIGHTON

Client: BHCC

Contract value: £2,067,913

Edburton Contractors Ltd (ECL) acted as Principal Contractor in providing structural support to the main A259 at its junction with West Street and the Victorian seafront building known as Shelter Hall. Once the structural support works were completed ECL demolished the old building leaving the site safe and ready for development.

The environment was particularly challenging due to existing retail use of nearby arches, proximity to the i360 Observation tower, foot traffic along the beach walkway & road traffic / pedestrians on the A259 above.

Download this case study as PDF

Shelter Hall, Brighton, Phase 1 of 3

Client: BHCC

Client Contact: Leon Bellis, BHCC Project Manager

Contract Start: March 2017

Contract Completion: November 2017

Value: £2,067,913

Description of Contract & Scope

The project successfully delivered the enabling of the existing structure and surrounding landscape. This was vital for securing of the next tranche of funding in Phase 2 of the development, which was to be construction of the new Shelter Hall. This finally culminated in it’s completion with Phase 3 at the end of 2021 – all of which Edburton were the principal contractor for.

The environment was particularly challenging due to existing retail use of nearby arches, proximity to the i360 Observation tower, foot traffic along the beach walkway & road traffic / pedestrians on the A259 above.

Delivery Principles

ECL were engaged on a negotiated fee basis through its then Term Highways Maintenance Contract amended to suit the following disciplines:

- Design responsibility for Temporary Works

- Contract specific insurance to protect Clients’ risk

- Contiguously piled temporary retaining wall

- Screw piles and raking shores for permanent works pending construction of the new building

- Demolition of the old Shelter Hall Structure.

A dedicated design team was established prior to commencement including:

- Clients Representative – Leon Bellis

- Structural Engineers – HOP

- CAT 3 Structural Engineers – Tony Gee & Partners

- Contractors Team – Edburton

Regular meetings were held stating in January 2017 (see attached Q11.4 Diagram 01 for example) to ensure that strict control was maintained:

- Designers Risk Assessments and subsequent Contractors RAMS

- Surety of maintaining the integrity of the existing Highway Asset (A259)

- Public liaison

- Cost monitoring

- Future development of the new Shelter Hall building

Risk Management and Scheme Challenges

Through Early Contractor Input and holding regular progress / design meetings the following design methodology was jointly agreed and undertaken:

- Installation of a contiguously piled retaining wall with 600mm diameter piles up to 20.0m deep plus an RC capping beam. This was particularly challenging due to a 3.0t weight limit over a large footprint of the site

- Temporary RC bases within the original building supported on mechanical screw piles to be used for temporary propping prior to demolition

- Permanent RC retaining walls within the original building prior to demolition to be used as temporary works during demolition

- Installation of RMD Kiwkform raking shores

- Robotic and traditional demolition

Emergency Work Planning

Due to the nature of the environment and the proximity to the sea we had to react within 24hours to adverse weather warnings to protect against beach erosion which threatened to undermine the site compound which included all welfare, contractors and client offices, parking and storage.

Through ECL owning and operating its own haulage fleet, including a 42.0 GVW low loader along with a large fleet of 3.5t – 25.0t 360 excavators it was able to provide labour and plant at very short notice to replenish shingle

Innovation

Due to the 3.0t weight limit imposed on the Shelter Hall roof we had a very limited footprint within which to operate. Through early engagement with piling specialists Van Elle to select a compact but high performing piling rig, use of the lower prom for craneage and the storage of reinforcement we were able to keep all pedestrian and vehicular routes open as well as having zero effect on neighbouring business premises.

Outcome – Budget, Schedule and Quality

The project successfully delivered the ability for the next phase of the development which was to be construction of the new Shelter Hall.

The project demonstrated ECL’s ability to achieve BHCC’s key outcomes for this Highways Services Contract as follows:

- BHCC Key Outcomes: Project Achievements

- Environmental: Worked to correct beach erosion. Demolition waste removed for recycling.

- Cost management: Cost control undertaken closely with the Client

- Customer satisfaction: Successful completion facilitated the next phase of building works

- Quality assurance: Innovative techniques introduced to solve problems

- Safety: Pedestrians and motorists safely segregated from the works. All works planned and executed to ensure ongoing structural integrity

- Social value: No disruption to adjacent businesses. Prom remained open for pedestrians

- Schedule management: Works undertaken to planned programme

- Well planned Permits: Works undertaken under BHCC Permit

STONEHAM PARK SUDS, BRIGHTON

Client: Brighton and Hove City Council

Contract value: £38k

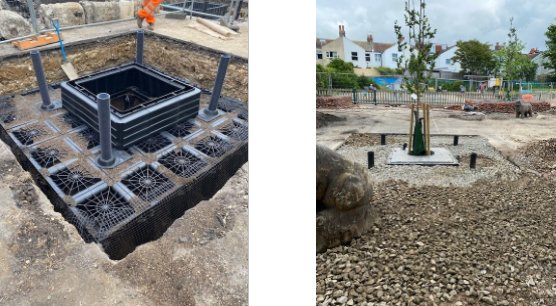

Edburton was employed as the main contractor to install a trial of 5 SUDS tree pits.

- To work as a solution to adding soakaway capacity in areas with flooding hotspots.

- 2 hybrid cell systems for sustainable urban drainage

- 3 structural soil systems (Stockholm), 1 below ground and 2 with gabions

- With added root inspection wells for future observation

- Planted with resistant Elms

Download this case study as PDF

Stoneham Park SUDS, Brighton

Client: BHCC

Description of Works

Brighton and Hove City Council instructed Edburton Contractors to install 5 SUDS, Sustainable urban drainage system, tree pits in Stoneham Park. This is a busy area with a children’s play park and adult sports classes and was the ideal location to trial various solutions to alleviate urban flooding.

The decision was made by BHCC and its Parks department to trial an ACO system, a Green Blue Urban system, and 3 variations on Stockholm tree pits. 2 tree pits had gabions with an oak top added for extra seating in the park so parents could supervise their children playing.

This trial was to find the differences in the tree pits and which solution and features would work best at alleviating surface water run-off from highways to reduce the stress on the local drainage system and then be used for future highways projects.

The benefits of these types of tree pits are the reduction in surface run-off into existing systems that are currently getting overwhelmed, they reduce the pollutants in the water, provide resilience to drought for the trees and contribute to urban greening. They help ease flood risk areas, improve the water quality and boost biodiversity, so it’s a great solution by combining modern drainage processes and the natural water cycle.

Method of Operations

The first step for the Aco and Green Blue systems was for the team to excavate and create a solid sub-base before laying a hessian membrane to prevent small fines clogging the drainage whilst the soil settles.

The cell systems were then installed and held in a rigid position by adding the side panels and some of the lids before filling them with soil. An excavator was used to fill the main void in the pit and then the team shovelled the soil by hand into the voids in the cells.

Aeration wells and inspection wells were installed for tree health and for future observations, and then the permeable mesh was laid over the cell system and tree planted before finishing with type 1 material and a surface course to mimic the highway construction.

The Stockholm tree pits started the same way with the team excavating and adding a solid sub-base. Next the variations; adding a concrete planting frame, mixing a combination of materials/ structural soil ( biochar, compost soil and aggregate stone ) which was done using the excavator and washing these materials into each other in the pit void. The team added the materials in layers compacting each layer before planting the tree into the planting frame, adding an aeration well and finishing the surface with permeable paving. Large gabions were constructed around 2 of the tree pits on site and filled with recycled material and topped with oak sleepers.

Risk Management

The area of works and surrounding protection zone were barriered off using Heras panels and one of the entrances to the park was permanently closed during the construction.

Signage was installed and attached to the Heras panels at various intervals around the site.

Deliveries and muck away were undertaken with a banksman on site and not after 15.30 hours when the park was noticeably busier with members of the public.

CLIENTS

CAPABILITY

For Soakaways, we can do this and that.

OUR SERVICES

LOCAL AUTHORITY

Edburton has over fifty years’ experience on Local Authority work. These have ranged from small scale maintenance contracts to large multi-million pound and framework civil engineering projects, these include:

COMMERCIAL DRAINAGE & UTILITIES

Edburton has worked extensively for private clients and local districts and authorities on numerous drainage projects for over 50 years.

We range from 24 hour round the clock emergency relief, to the construction of complete new systems. These services include any of all of the following:

COMMERCIAL DRAINAGE & UTILITIES

Edburton has worked extensively for private clients and local districts and authorities on numerous drainage projects for over 50 years.

We range from 24 hour round the clock emergency relief, to the construction of complete new systems. These services include any of all of the following:

HARD & SOFT LANDSCAPING

Edburton carries out both hard and soft landscaping for local authority and private clients, ranging from a few thousand pounds to multi million pound developments.

RECYCLED AGGREGRATE

Edburton’s recycled aggregates can be used for the construction of paths, roads and car parks either as a base or as a finished surface.

MOT Type 1 / 6F5 (as above) / 40-75mm Crushed Concrete

RECYCLED AGGREGRATE

Edburton’s recycled aggregates can be used for the construction of paths, roads and car parks either as a base or as a finished surface.

MOT Type 1 / 6F5 (as above) / 40-75mm Crushed Concrete